Pengenalan Produk

Visi Generasi Seterusnya: Teknologi Permukaan Digital Bentuk Bebas

Kanta Progresif Digital Bentuk Bebas mewakili kemuncak mutlak sains oftalmik moden. Tidak seperti progresif tradisional yang dibuang daripada acuan tetap, kanta Freeform kami dicipta menggunakan teknologi pemusing titik berlian CNC berketepatan tinggi. Proses "Digital Surfacing" ini membolehkan reka bentuk kanta dikira dan diukir titik demi titik pada permukaan belakang kanta dengan ketepatan 0.01 dioptri. Ini mencipta pengalaman penglihatan yang disesuaikan secara unik dengan preskripsi khusus dan geometri bingkai pemakai. Kelebihan utama teknologi Freeform ialah pengurangan dramatik herotan periferi (astigmatisme), yang merupakan aduan biasa dalam varifokal konvensional. Dengan mengoptimumkan koridor untuk penglihatan jarak, pertengahan dan dekat, kami menyediakan medan visual sehingga 30% lebih luas dan lebih jelas. Sama ada anda memandu, bekerja pada komputer atau membaca telefon pintar, peralihan antara titik fokus adalah lancar, semula jadi dan memerlukan pergerakan kepala yang minimum. Reka bentuk progresif digital kami juga menggabungkan pengoptimuman "Dalam set", yang menjajarkan zon penglihatan dekat dengan sempurna dengan penumpuan semula jadi mata semasa membaca. Digabungkan dengan resin indeks ultra tinggi dan salutan berbilang canggih, kanta Freeform menawarkan pengalaman visual yang paling selesa, definisi tinggi dan mudah disesuaikan yang terdapat di pasaran hari ini.

| Surface Tech | Bentuk Bebas Digital Bahagian Belakang |

| Panjang Koridor | 11mm, 13mm, 15mm, 17mm |

| Indeks | 1.56, 1.61, 1.67, 1.74 |

Sorotan Teknologi: Monomer Premium dan Integriti Salutan

- Pemilihan Monomer Ketulenan Tinggi: Kami secara eksklusif menggunakan monomer berprestasi tinggi (mis., siri MR) untuk mencapai kekuatan tegangan dan ketulenan optik yang unggul, menghasilkan kejelasan yang sangat baik dan risiko minimum menguning dari semasa ke semasa.

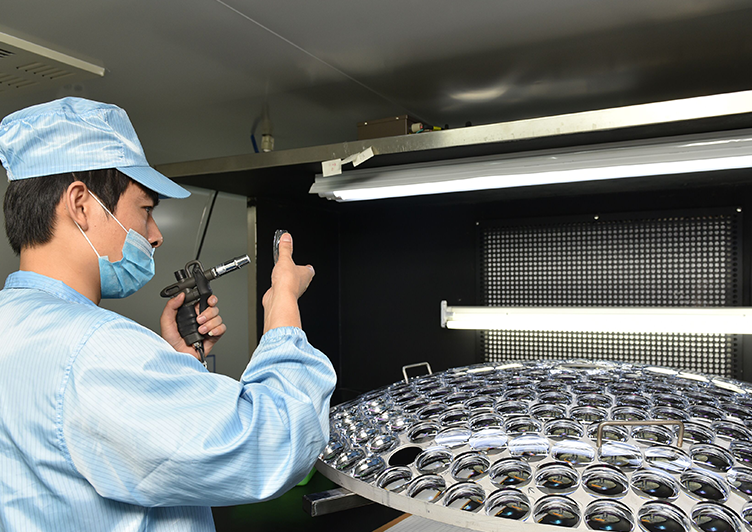

- Proses Tuangan Cecair Ketepatan: Kanta dihasilkan melalui kaedah tuangan cecair terkawal yang memastikan ketumpatan bahan seragam dan konsistensi indeks biasan merentas keseluruhan kosong, yang penting untuk zon kuasa terapeutik yang tepat.

- Salutan Berbilang Vakum Lanjutan (SHMC): Salutan digunakan dalam ruang vakum tinggi, menggunakan pelbagai lapisan oksida logam untuk mencipta tindanan anti-reflektif yang tahan lama. Proses ini menjamin penghantaran cahaya maksimum dan silau minimum.

- Pengoptimuman Pengawetan Terma: Kitaran pengawetan haba yang perlahan dan tepat digunakan untuk memaksimumkan rintangan bahan terhadap tekanan dalaman, memastikan kanta siap kekal stabil dan sempurna dari segi optik dalam keadaan suhu yang berbeza-beza.

- Geometri Nyahfokus Periferi Bersepadu: Reka bentuk terapeutik direka bentuk ke dalam acuan itu sendiri untuk kanta tuang, atau digunakan melalui permukaan digital untuk kosong separuh siap, menjamin ketepatan dan konsistensi geometri zon kawalan rabun.

- Pembetulan Presbiopia Sepanjang Hari

- Kerja Digital Resolusi Tinggi

- Gaya Hidup Aktif dengan Fokus Berubah

- Medan Penglihatan Jelas Terluas Mungkin

- Hampir Tiada Kesan "Berenang" Periferi

- Ketepatan Kepersisan hingga 0.01 Diopter

-

0+

Pengalaman Bertahun

-

0㎡

Kawasan Loji

-

0+

Dieksport ke Negara

-

0juta kanta

Kapasiti Tahunan

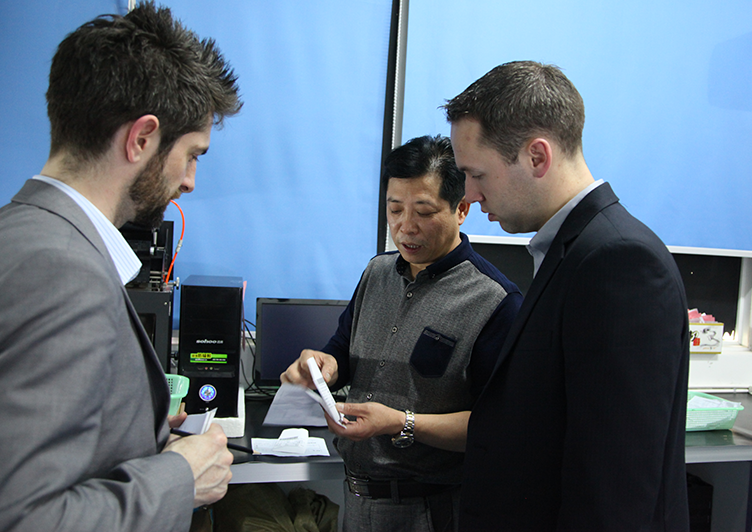

Penyesuaian

Disesuaikan Untuk Anda

Perniagaan

-

01

Keupayaan Penyesuaian Lengkap

-

02

Seni Bina Kanta Profesional

-

03

Penyesuaian Salutan Fungsian

-

04

Penyesuaian Rx Digital

-

05

Penjenamaan & Pembungkusan

-

06

Penghantaran & Sokongan

- S: Apakah yang menjadikan Freeform "Digital"?

- A: Preskripsi diukir oleh mesin pelarik berlian yang dikawal komputer untuk ketepatan yang melampau.

- S: Adakah mereka lebih mudah untuk menyesuaikan diri daripada progresif lama?

- A: Lebih mudah; herotan dikurangkan dengan ketara, menjadikan mereka berasa lebih semula jadi.

- S: Bolehkah saya menggunakannya untuk kerja komputer?

- A: Ya, zon perantaraan jauh lebih luas dalam reka bentuk Bentuk Bebas.

- S: Bolehkah saya meletakkannya dalam bingkai kecil?

- A: Ya, kami menawarkan reka bentuk "Koridor Pendek" khusus untuk bingkai kecil.

- S: Adakah mereka datang dalam indeks tinggi?

- A: Ya, ia tersedia dalam semua indeks sehingga 1.74.

- S: Adakah salutan Blue-Cut tersedia?

- A: Ya, ia sangat disyorkan untuk pengguna progresif digital.

- S: Mengapa ada masa utama?

- A: Setiap kanta adalah ciptaan digital yang dipesan lebih dahulu yang memerlukan pemprosesan makmal khusus.

- S: Adakah mereka membantu dengan pemanduan malam?

- A: Ya, ketepatan digital mengurangkan silau dan meningkatkan kontras.

- S: Apakah ukuran yang diperlukan?

- A: PD, ketinggian segmen, dan idealnya balut bingkai dan condong.

- S: Adakah mereka lebih mahal?

- A: Mereka adalah produk premium kerana teknologi canggih yang terlibat.

T/T, PayPal, Wayar. Masa Makmal Digital 12-15 Hari.

MOQ: 1 Pasang (Bespoke). Makmal Digital Disahkan.