Pengenalan Produk

Perlindungan Tiada tandingan: Kelebihan Polikarbonat 1.59

Apabila keselamatan dan ketahanan tidak boleh dirunding, kanta Polikarbonat 1.59 adalah pilihan utama. Pada asalnya dibangunkan untuk aplikasi aeroangkasa (visor topi keledar) dan tingkap kalis peluru, bahan ini hampir tidak boleh dihancurkan di bawah penggunaan optik biasa. Polikarbonat ialah bahan termoplastik yang diacukan suntikan dan bukannya tuang, menghasilkan kanta yang 10 kali lebih tahan hentaman daripada plastik atau kaca standard. Ini menjadikannya standard wajib untuk cermin mata kanak-kanak, cermin mata sukan dan cermin mata keselamatan industri. Di luar kekuatannya yang luar biasa, indeks 1.59 adalah sangat nipis dan merupakan bahan paling ringan dalam industri optik (dengan graviti tentu 1.20). Setiap 1.59 kanta yang kami hasilkan dilengkapi dengan perlindungan 100% UV400 yang wujud, menghalang semua sinaran suria yang berbahaya tanpa memerlukan salutan tambahan. Untuk mengatasi kelembutan semula jadi bahan, kami menggunakan lapisan keras bersambung silang khusus yang memberikan rintangan calar yang unggul. Untuk atlet, pelajar aktif atau sesiapa sahaja dalam persekitaran berisiko tinggi, kanta Polikarbonat 1.59 memberikan ketenangan fikiran bahawa mata mereka dilindungi oleh penghalang gred balistik yang kekal jernih dan selesa sepanjang hari.

| Indeks Biasan | 1.586 / 1.59 |

| Penilaian Impak | ANSI Z87.1 / EN166 |

| Nilai Abbe | 30 |

Sorotan Teknologi: Monomer Premium dan Integriti Salutan

- Pemilihan Monomer Ketulenan Tinggi: Kami secara eksklusif menggunakan monomer berprestasi tinggi (mis., siri MR) untuk mencapai kekuatan tegangan dan ketulenan optik yang unggul, menghasilkan kejelasan yang sangat baik dan risiko minimum menguning dari semasa ke semasa.

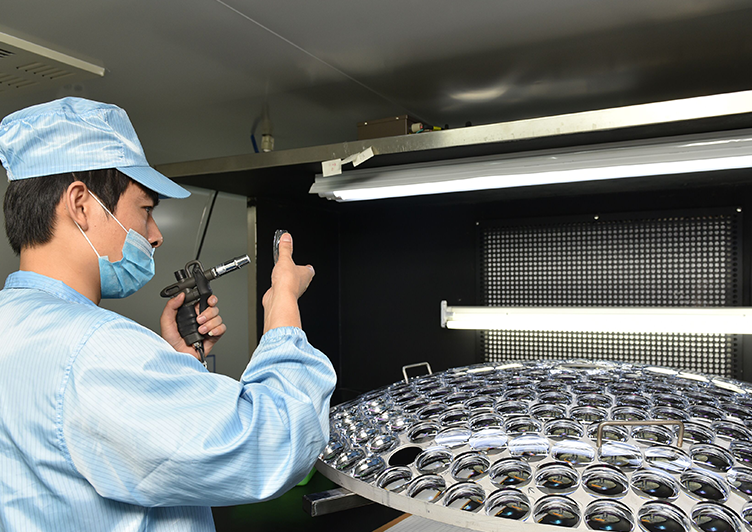

- Proses Tuangan Cecair Ketepatan: Kanta dihasilkan melalui kaedah tuangan cecair terkawal yang memastikan ketumpatan bahan seragam dan konsistensi indeks biasan merentas keseluruhan kosong, yang penting untuk zon kuasa terapeutik yang tepat.

- Salutan Berbilang Vakum Lanjutan (SHMC): Salutan digunakan dalam ruang vakum tinggi, menggunakan pelbagai lapisan oksida logam untuk mencipta tindanan anti-reflektif yang tahan lama. Proses ini menjamin penghantaran cahaya maksimum dan silau minimum.

- Pengoptimuman Pengawetan Terma: Kitaran pengawetan haba yang perlahan dan tepat digunakan untuk memaksimumkan rintangan bahan terhadap tekanan dalaman, memastikan kanta siap kekal stabil dan sempurna dari segi optik dalam keadaan suhu yang berbeza-beza.

- Geometri Nyahfokus Periferi Bersepadu: Reka bentuk terapeutik direka bentuk ke dalam acuan itu sendiri untuk kanta tuang, atau digunakan melalui permukaan digital untuk kosong separuh siap, menjamin ketepatan dan konsistensi geometri zon kawalan rabun.

- Kacamata Kanak-kanak & Remaja

- Sukan & Gaya Hidup Aktif

- Keselamatan & Kerja Industri

- Hampir Tidak Boleh Dipecahkan

- Keselesaan Ultra-Ringan

- Perlindungan UV 100% yang wujud

-

0+

Pengalaman Bertahun

-

0㎡

Kawasan Loji

-

0+

Dieksport ke Negara

-

0juta kanta

Kapasiti Tahunan

Penyesuaian

Disesuaikan Untuk Anda

Perniagaan

-

01

Keupayaan Penyesuaian Lengkap

-

02

Seni Bina Kanta Profesional

-

03

Penyesuaian Salutan Fungsian

-

04

Penyesuaian Rx Digital

-

05

Penjenamaan & Pembungkusan

-

06

Penghantaran & Sokongan

- S: Bolehkah kanta polikarbonat pecah?

- A: Mereka sangat tahan dan akan retak dan bukannya hancur di bawah kuasa yang melampau.

- S: Adakah ia sesuai untuk bingkai tanpa bingkai?

- A: Ya, mereka sangat disyorkan untuk reka bentuk tanpa bingkai dan separa tanpa bingkai.

- S: Adakah mereka menggaru lebih daripada CR-39?

- A: Bahannya lebih lembut, jadi kami menyertakan kot keras bertetulang untuk melindunginya.

- S: Adakah mereka berat?

- A: Tidak, ia adalah kanta paling ringan yang terdapat di pasaran.

- S: Adakah mereka mempunyai perlindungan UV terbina dalam?

- A: Ya, perlindungan 100% UV400 adalah sifat semula jadi polikarbonat.

- S: Adakah mereka sejelas 1.50?

- A: Ia mempunyai nilai Abbe yang lebih rendah (30), tetapi salutan moden meminimumkan sebarang isu visual.

- S: Bolehkah saya menggunakannya untuk sukan?

- A: Ya, ia adalah piawaian emas untuk sukan dan cermin mata aktiviti tinggi.

- S: Bagaimana ia dihasilkan?

- A: Melalui proses pengacuan suntikan berketepatan tinggi.

- S: Adakah Blue-Cut tersedia?

- A: Ya, kami menawarkan polikarbonat Potongan Biru untuk keselamatan digital.

- S: Adakah ia sesuai untuk preskripsi berkuasa tinggi?

- A: Ia cukup nipis untuk kuasa sederhana, tetapi 1.67 lebih baik untuk kuasa sangat tinggi.

T/T, Kad Kredit. Masa Utama 10-12 Hari.

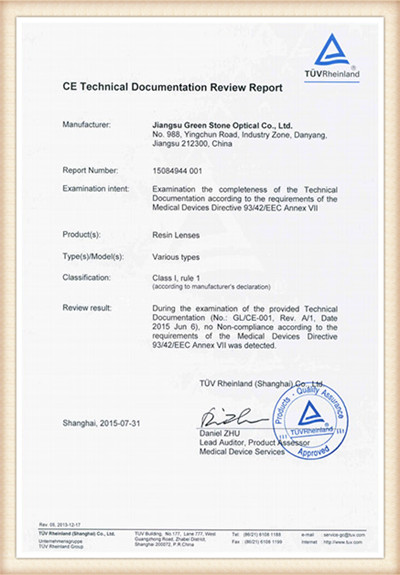

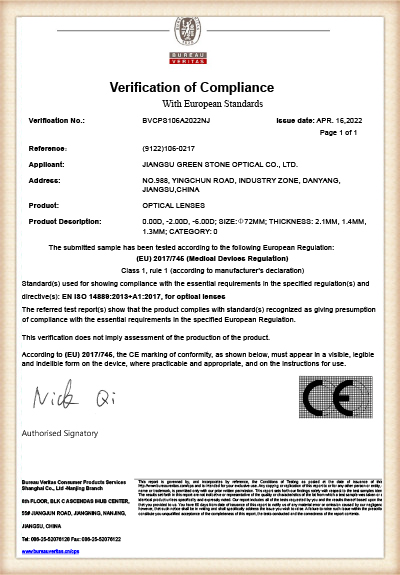

MOQ: 50 pasang. Diperakui Keselamatan.