Pengenalan Produk

Ketelusan Visual: Fizik Sistem Anti-Reflektif Berbilang Lapisan

Kanta resin standard yang tidak bersalut memantulkan sebahagian besar cahaya kejadian, mengakibatkan kehilangan penghantaran dan penciptaan imej hantu yang mengganggu. Kanta Anti-Reflective Hard Multi-Coating (HMC) kami menggunakan prinsip gangguan yang merosakkan untuk menghapuskan pantulan permukaan secara hampir. Dalam ruang vakum tinggi khusus, 12 hingga 16 lapisan individu oksida logam—seperti Zirkonium dan Titanium—didepositkan pada permukaan kanta dengan ketepatan atom. Lapisan ini direka bentuk untuk mempunyai indeks biasan dan ketebalan khusus yang membatalkan gelombang cahaya yang dipantulkan merentasi keseluruhan spektrum yang boleh dilihat. Ini meningkatkan penghantaran cahaya lensa kepada lebih 99%, memberikan tahap kejelasan visual yang dirasakan hampir seperti lensa tidak ada. Bagi pemakai, ini diterjemahkan kepada penglihatan yang lebih tajam, kontras yang lebih baik dalam keadaan cahaya malap dan pengurangan ketara dalam silau daripada lampu hadapan semasa pemanduan malam. Secara luaran, rawatan HMC menghilangkan "kilat putih" dari kanta, membolehkan orang lain melihat mata pemakai dengan jelas. Untuk memastikan ketahanan jangka panjang, timbunan AR dilabuhkan oleh lapisan keras berketumpatan tinggi (HC) yang melindungi substrat resin yang agak lembut daripada calar. Gabungan seimbang prestasi optik dan daya tahan fizikal ini menjadikan HMC garis asas yang penting untuk semua cermin mata pembetulan berkualiti tinggi.

| Penghantaran Cahaya | > 99.2% |

| Lapisan Salutan | Timbunan 16 Lapisan Dua Sisi |

| Gred Kekerasan | 6H - 8H (Ujian Bayer) |

Sorotan Teknologi: Monomer Premium dan Integriti Salutan

- Pemilihan Monomer Ketulenan Tinggi: Kami secara eksklusif menggunakan monomer berprestasi tinggi (mis., siri MR) untuk mencapai kekuatan tegangan dan ketulenan optik yang unggul, menghasilkan kejelasan yang sangat baik dan risiko minimum menguning dari semasa ke semasa.

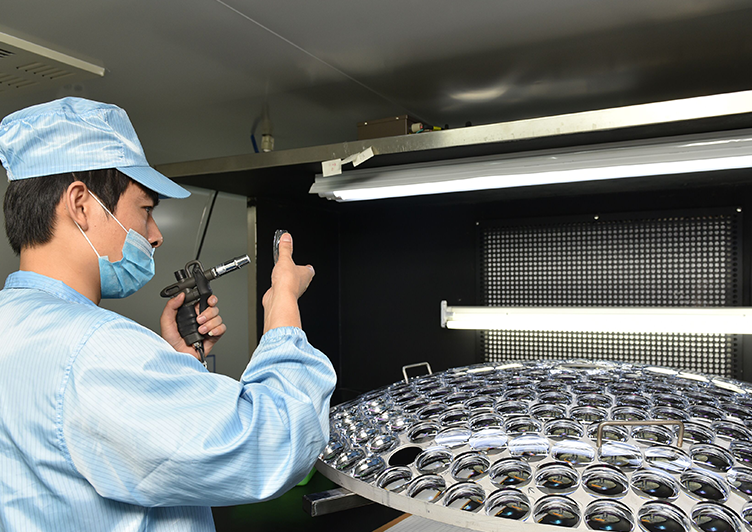

- Proses Tuangan Cecair Ketepatan: Kanta dihasilkan melalui kaedah tuangan cecair terkawal yang memastikan ketumpatan bahan seragam dan konsistensi indeks biasan merentas keseluruhan kosong, yang penting untuk zon kuasa terapeutik yang tepat.

- Salutan Berbilang Vakum Lanjutan (SHMC): Salutan digunakan dalam ruang vakum tinggi, menggunakan pelbagai lapisan oksida logam untuk mencipta tindanan anti-reflektif yang tahan lama. Proses ini menjamin penghantaran cahaya maksimum dan silau minimum.

- Pengoptimuman Pengawetan Terma: Kitaran pengawetan haba yang perlahan dan tepat digunakan untuk memaksimumkan rintangan bahan terhadap tekanan dalaman, memastikan kanta siap kekal stabil dan sempurna dari segi optik dalam keadaan suhu yang berbeza-beza.

- Geometri Nyahfokus Periferi Bersepadu: Reka bentuk terapeutik direka bentuk ke dalam acuan itu sendiri untuk kanta tuang, atau digunakan melalui permukaan digital untuk kosong separuh siap, menjamin ketepatan dan konsistensi geometri zon kawalan rabun.

- Pemanduan waktu malam yang selamat

- Fotografi dan videografi profesional

- Interaksi sosial dan profesional

- Menghapuskan imej hantu yang mengganggu dan silau

- Memaksimumkan aliran cahaya untuk penglihatan yang lebih baik

- Meningkatkan penampilan estetik si pemakai

-

0+

Pengalaman Bertahun

-

0㎡

Kawasan Loji

-

0+

Dieksport ke Negara

-

0juta kanta

Kapasiti Tahunan

Penyesuaian

Disesuaikan Untuk Anda

Perniagaan

-

01

Keupayaan Penyesuaian Lengkap

-

02

Seni Bina Kanta Profesional

-

03

Penyesuaian Salutan Fungsian

-

04

Penyesuaian Rx Digital

-

05

Penjenamaan & Pembungkusan

-

06

Penghantaran & Sokongan

- S: Mengapa kanta saya mempunyai pantulan hijau atau biru?

- A: Ini ialah warna pantulan sisa salutan AR, yang menunjukkan kefungsiannya.

- S: Adakah salutan HMC tahan calar?

- A: Ya, ia termasuk lapisan lapisan keras primer khusus untuk rintangan calar.

- S: Bolehkah salutan mengelupas?

- A: Proses pemendapan vakum kami memastikan ikatan kekal yang tidak akan terkelupas di bawah penggunaan biasa.

- S: Adakah ia membantu dengan ketegangan mata komputer?

- A: Ya, dengan mengurangkan silau daripada skrin digital dan pencahayaan atas.

- S: Adakah kanta HMC lebih sukar dibersihkan?

- A: Tidak jika ia termasuk lapisan atas hidrofobik, yang dilakukan oleh kanta HMC kami.

- S: Bolehkah saya mendapatkan HMC pada kanta indeks tinggi?

- A: Ia amat disyorkan untuk kanta indeks tinggi, kerana ia secara semula jadi memantulkan lebih banyak cahaya.

- S: Adakah HMC menyekat UV?

- A: HMC adalah untuk penghantaran cahaya; Perlindungan UV terbina dalam bahan kanta itu sendiri.

- S: Adakah ia sesuai untuk cermin mata hitam?

- A: Ya, ia sering digunakan pada permukaan belakang cermin mata hitam untuk menghentikan silau belakang.

- S: Berapa lama salutan tahan?

- A: Dengan penjagaan yang betul, salutan bertahan selagi preskripsi adalah sah.

- S: Adakah warna salutan berubah dari semasa ke semasa?

- A: Tidak, warna adalah hasil daripada ketebalan lapisan, yang stabil.

T/T, PayPal, Wayar. Pengeluaran Pantas 7 Hari.

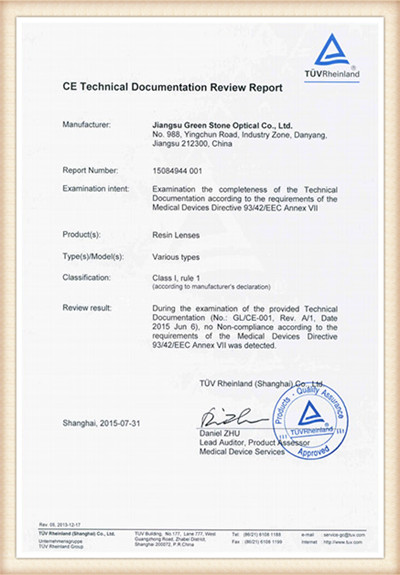

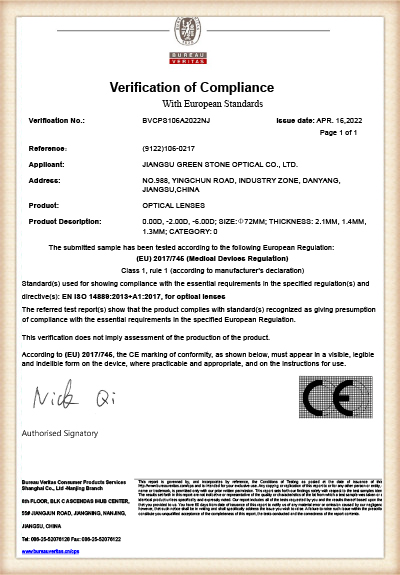

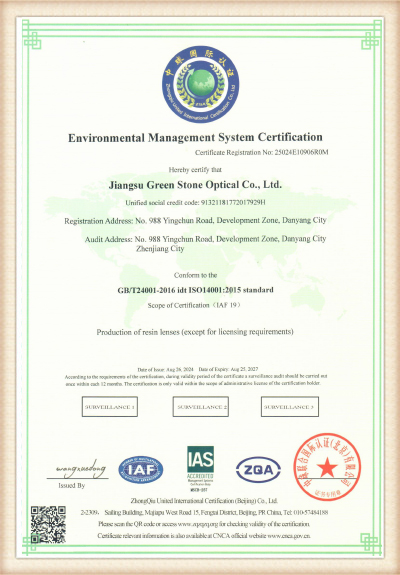

MOQ: 100 Pasang. Pematuhan Standard CE dan ISO.