Pengenalan Produk

Standard Prestasi Tiga: Ketahanan, Kejelasan dan Keselesaan Ringan

Trivex mewakili lonjakan revolusioner dalam sains bahan optik, pada asalnya dibangunkan untuk ketahanan melampau dalam aplikasi aeroangkasa dan ketenteraan. Sebagai pra-polimer poliuretana berasaskan nitrogen, Trivex menawarkan "ancaman tiga kali ganda" sifat unik yang tidak dapat dipadankan oleh resin tradisional. Pertama, rintangan hentamannya tidak dapat ditandingi, memenuhi piawaian keselamatan berkelajuan tinggi tertinggi, menjadikannya hampir tidak boleh dipecahkan dalam keadaan biasa dan bahkan melampau. Kedua, tidak seperti polikarbonat—yang berkongsi kekuatannya tetapi sering mengalami ketulenan optik yang lebih rendah—Trivex mempunyai nilai Abbe yang mengagumkan iaitu 45. Ini memastikan penyimpangan kromatik yang minimum, memberikan pemakai penglihatan kontras tinggi yang jelas yang penting untuk kedua-dua sukan dan tugasan berketepatan tinggi. Akhir sekali, Trivex ialah bahan kanta paling ringan di pasaran hari ini, dengan graviti tentu hanya 1.11 g/cm³, bermakna ia terapung di atas air dan mengurangkan berat cermin mata pada batang hidung dengan ketara. Kekuatan tegangannya yang unggul menjadikannya pilihan muktamad untuk bingkai tanpa bingkai dan separa tanpa bingkai (lekap gerudi), kerana bahan itu tahan retak dan mengelupas pada titik tegasan lebih baik daripada mana-mana resin indeks tinggi. Bagi individu aktif, kanak-kanak dan mereka yang menuntut gabungan keselamatan dan kesempurnaan optik yang muktamad, Trivex ialah piawaian emas tanpa kompromi dalam teknologi kanta moden.

| Indeks Biasan | 1.53 |

| Nilai Abbe | 45 (Kejelasan Tinggi) |

| Graviti Tertentu | 1.11 g/cm³ (Ultra-Ringan) |

Sorotan Teknologi: Monomer Premium dan Integriti Salutan

- Pemilihan Monomer Ketulenan Tinggi: Kami secara eksklusif menggunakan monomer berprestasi tinggi (mis., siri MR) untuk mencapai kekuatan tegangan dan ketulenan optik yang unggul, menghasilkan kejelasan yang sangat baik dan risiko minimum menguning dari semasa ke semasa.

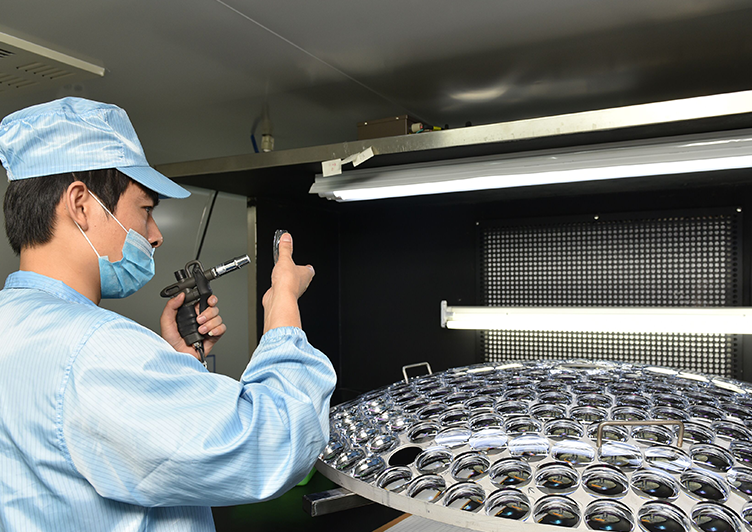

- Proses Tuangan Cecair Ketepatan: Kanta dihasilkan melalui kaedah tuangan cecair terkawal yang memastikan ketumpatan bahan seragam dan konsistensi indeks biasan merentas keseluruhan kosong, yang penting untuk zon kuasa terapeutik yang tepat.

- Salutan Berbilang Vakum Lanjutan (SHMC): Salutan digunakan dalam ruang vakum tinggi, menggunakan berbilang lapisan oksida logam untuk mencipta tindanan anti-reflektif yang tahan lama. Proses ini menjamin penghantaran cahaya maksimum dan silau minimum.

- Pengoptimuman Pengawetan Terma: Kitaran pengawetan haba yang perlahan dan tepat digunakan untuk memaksimumkan rintangan bahan terhadap tekanan dalaman, memastikan kanta siap kekal stabil dan sempurna dari segi optik dalam keadaan suhu yang berbeza-beza.

- Geometri Nyahfokus Periferi Bersepadu: Reka bentuk terapeutik direka bentuk ke dalam acuan itu sendiri untuk kanta tuang, atau digunakan melalui permukaan digital untuk kosong separuh siap, menjamin ketepatan dan konsistensi geometri zon kawalan rabun.

- Kacamata Kanak-kanak dan Remaja

- Sukan dan Olahraga Aksi Tinggi

- Bingkai Premium Tanpa Rimless dan Drill-Mount

- Rintangan dan Keselamatan Kesan Unggul

- Ketulenan Optik Cemerlang (Penyimpangan Rendah)

- Sangat Ringan untuk Pakaian Sepanjang Hari

-

0+

Pengalaman Bertahun

-

0㎡

Kawasan Loji

-

0+

Dieksport ke Negara

-

0juta kanta

Kapasiti Tahunan

Penyesuaian

Disesuaikan Untuk Anda

Perniagaan

-

01

Keupayaan Penyesuaian Lengkap

-

02

Seni Bina Kanta Profesional

-

03

Penyesuaian Salutan Fungsian

-

04

Penyesuaian Rx Digital

-

05

Penjenamaan & Pembungkusan

-

06

Penghantaran & Sokongan

- S: Adakah Trivex lebih kuat daripada Polikarbonat?

- A: Kedua-duanya menawarkan rintangan hentaman yang melampau, tetapi Trivex mempunyai kejelasan optik yang unggul dan rintangan kimia.

- S: Mengapakah Trivex disyorkan untuk bingkai tanpa bingkai?

- A: Kekuatan tegangannya yang tinggi menghalang kanta daripada retak di sekeliling lubang gerudi.

- S: Adakah Trivex mempunyai warna kuning?

- A: Tidak, ia adalah bahan sejernih kristal dengan transmisi cahaya tinggi.

- S: Berapa banyak lebih ringan daripada plastik standard?

- A: Ia lebih kurang 20-30% lebih ringan daripada resin indeks 1.50 standard.

- S: Adakah ia menghalang sinaran UV?

- A: Ya, Trivex secara semulajadi menyekat 100% sinaran UV400 tanpa salutan tambahan.

- S: Bolehkah Trivex diwarnakan?

- A: Ya, ia menerima warna dengan baik, walaupun prosesnya berbeza sedikit daripada CR-39.

- S: Adakah ia datang dengan salutan anti-reflektif?

- A: Sudah tentu, kanta Trivex kami adalah standard dengan SHMC premium.

- S: Adakah ia sesuai untuk preskripsi tinggi?

- A: Dengan indeks 1.53, yang terbaik adalah untuk preskripsi rendah hingga sederhana.

- S: Adakah ia tahan terhadap bahan kimia?

- A: Ya, ia lebih tahan terhadap bahan kimia isi rumah dan penyembur rambut daripada polikarbonat.

- S: Adakah Trivex sesuai untuk cermin mata keselamatan?

- A: Ya, ia digunakan secara meluas untuk aplikasi keselamatan industri dan halaju tinggi.

T/T, PayPal, Pindahan Kawat. Penghantaran 7-10 Hari.

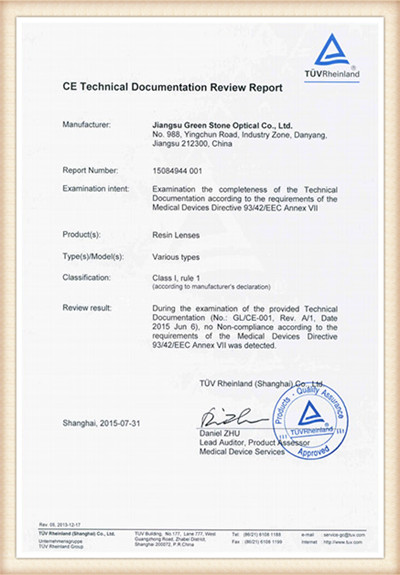

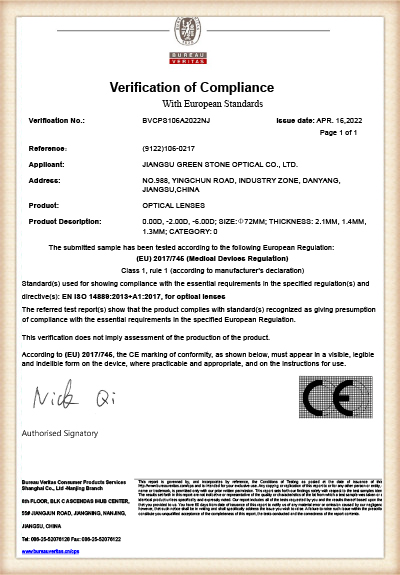

MOQ: 50 pasang. Gred Halaju Tinggi yang diperakui.