Pengenalan Produk

Pengoptimuman Struktur: Kejuruteraan Kanta Kuasa Tinggi Lentikular

Pesakit yang mengalami ralat biasan yang melampau—seperti rabun melebihi -15.00D atau hiperopia melebihi 10.00D—selalunya menghadapi cabaran untuk memakai kanta yang terlalu berat atau terlalu tebal untuk bingkai standard. Kanta Lentikular kami menyediakan penyelesaian geometri khusus dengan menumpukan kuasa pembetulan dalam "mangkuk optik" pusat atau apertur. Kawasan pembawa di sekeliling menipis dengan ketara, bertindak sebagai sokongan struktur dan bukannya permukaan biasan. Pendekatan ini mengurangkan jumlah keseluruhan kanta sehingga 60%, secara drastik mengurangkan berat pada hidung dan telinga pemakai. Menggunakan lengkung bukan sfera berketepatan tinggi, kami memastikan peralihan antara zon optik (biasanya diameter 30mm hingga 40mm) dan zon pembawa adalah selancar mungkin untuk meminimumkan artifak visual persisian. Setiap kanta dikira berdasarkan dimensi bingkai tertentu untuk memastikan zon optik berpusat dengan sempurna di atas murid. Dengan menggunakan bahan indeks tertinggi di dunia, seperti resin 1.74 atau kaca 1.90, dalam kombinasi dengan geometri lentikular, kami menukar kanta "botol kok" yang tidak boleh dipakai kepada alat optik yang berfungsi, ringan dan boleh diterima secara estetik. Teknologi ini penting untuk pesakit aphakic dan mereka yang mempunyai rabun patologi tinggi, menawarkan mereka keupayaan untuk memilih bingkai yang bergaya dan menikmati keselesaan sepanjang hari tanpa mengorbankan kejelasan preskripsi mereka.

| Diameter Apertur | 30mm, 34mm, 40mm (Boleh Disesuaikan) |

| Pengurangan Berat Badan | Sehingga 60% berbanding Reka Bentuk Standard |

| Preskripsi Maks | Sehingga -35.00D / 30.00D |

Sorotan Teknologi: Monomer Premium dan Integriti Salutan

- Pemilihan Monomer Ketulenan Tinggi: Kami secara eksklusif menggunakan monomer berprestasi tinggi (mis., siri MR) untuk mencapai kekuatan tegangan dan ketulenan optik yang unggul, menghasilkan kejelasan yang sangat baik dan risiko minimum menguning dari semasa ke semasa.

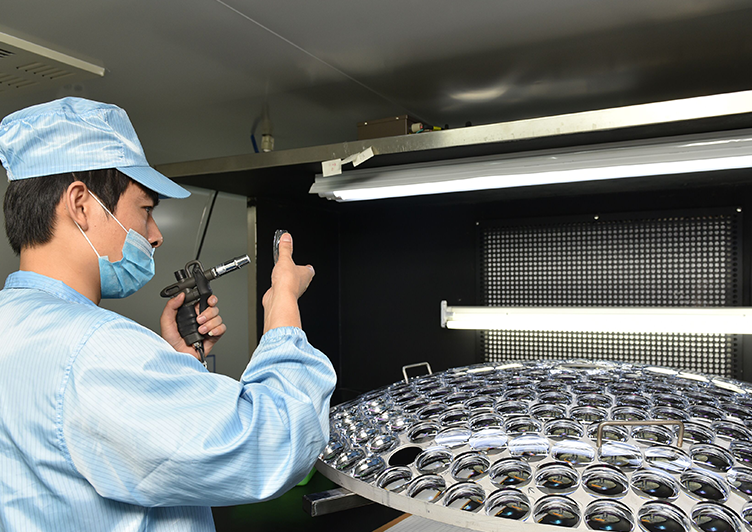

- Proses Tuangan Cecair Ketepatan: Kanta dihasilkan melalui kaedah tuangan cecair terkawal yang memastikan ketumpatan bahan seragam dan konsistensi indeks biasan merentas keseluruhan kosong, yang penting untuk zon kuasa terapeutik yang tepat.

- Salutan Berbilang Vakum Lanjutan (SHMC): Salutan digunakan dalam ruang vakum tinggi, menggunakan berbilang lapisan oksida logam untuk mencipta tindanan anti-reflektif yang tahan lama. Proses ini menjamin penghantaran cahaya maksimum dan silau minimum.

- Pengoptimuman Pengawetan Terma: Kitaran pengawetan haba yang perlahan dan tepat digunakan untuk memaksimumkan rintangan bahan terhadap tekanan dalaman, memastikan kanta siap kekal stabil dan sempurna dari segi optik dalam keadaan suhu yang berbeza-beza.

- Geometri Nyahfokus Periferi Bersepadu: Reka bentuk terapeutik direka bentuk ke dalam acuan itu sendiri untuk kanta tuang, atau digunakan melalui permukaan digital untuk kosong separuh siap, menjamin ketepatan dan konsistensi geometri zon kawalan rabun.

- Miopia atau hiperopia yang melampau

- Aphakia dan pembetulan tinggi selepas pembedahan

- Pesakit yang memerlukan pengurangan berat maksimum

- Penipisan tepi yang tiada tandingan untuk kuasa ultra tinggi

- Secara dramatik mengurangkan keletihan pemakai dan tekanan hidung

- Membolehkan pemasangan preskripsi tinggi ke dalam bingkai standard

-

0+

Pengalaman Bertahun

-

0㎡

Kawasan Loji

-

0+

Dieksport ke Negara

-

0juta kanta

Kapasiti Tahunan

Penyesuaian

Disesuaikan Untuk Anda

Perniagaan

-

01

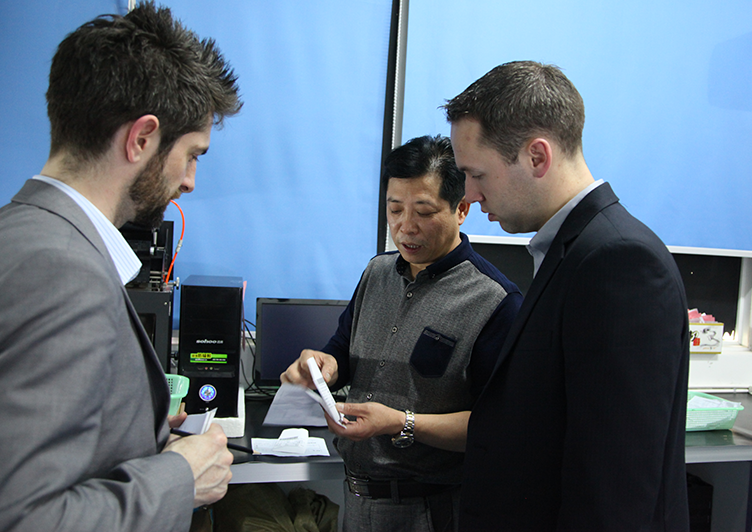

Keupayaan Penyesuaian Lengkap

-

02

Seni Bina Kanta Profesional

-

03

Penyesuaian Salutan Fungsian

-

04

Penyesuaian Rx Digital

-

05

Penjenamaan & Pembungkusan

-

06

Penghantaran & Sokongan

- S: Apakah kanta lentikular?

- A: Ia adalah kanta di mana hanya bahagian tengah mempunyai preskripsi, untuk mengurangkan ketebalan.

- S: Adakah orang akan melihat "bulatan" dalam kanta saya?

- A: Ya, garis peralihan samar kelihatan, tetapi ia jauh lebih nipis daripada kanta standard.

- S: Adakah ia mengehadkan bidang pandangan saya?

- A: Penglihatan pusat anda sempurna; penglihatan sisi anda terhad kepada saiz apertur.

- S: Bolehkah kanta ini dibuat dalam indeks 1.74?

- A: Ya, menggabungkan 1.74 dengan reka bentuk lentikular memberikan hasil yang paling nipis.

- S: Adakah ia sesuai untuk kanak-kanak?

- A: Ya, mereka sering digunakan untuk kanak-kanak dengan preskripsi tinggi kongenital.

- S: Bolehkah saya menambah warna pada kanta ini?

- A: Ya, mereka boleh diwarnakan atau dijadikan cermin mata hitam.

- S: Adakah bahagian pembawa lensa jelas?

- A: Ia telus, tetapi ia tidak memberikan penglihatan yang fokus.

- S: Adakah mereka memerlukan bingkai khas?

- A: Bingkai yang kecil dan lebih bulat adalah yang terbaik untuk memaksimumkan kesan lentikular.

- S: Bagaimana anda mengukur untuk ini?

- A: PD dan ketinggian yang tepat adalah penting untuk memusatkan mangkuk optik.

- S: Mengapa harganya lebih tinggi daripada kanta biasa?

- A: Ia pada asasnya adalah peranti perubatan yang ditempah khas yang direka khas.

T/T, Bank Wire. Masa Utama Pengisaran Tersuai 15-20 Hari.

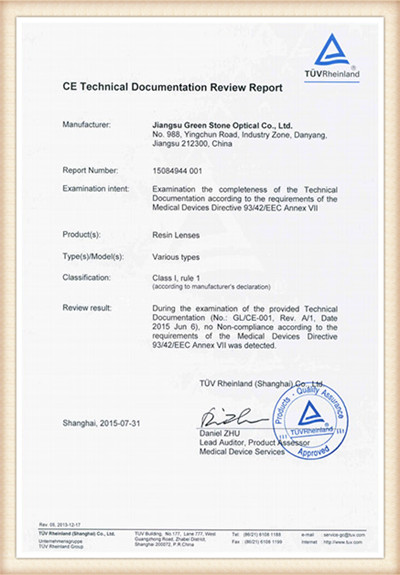

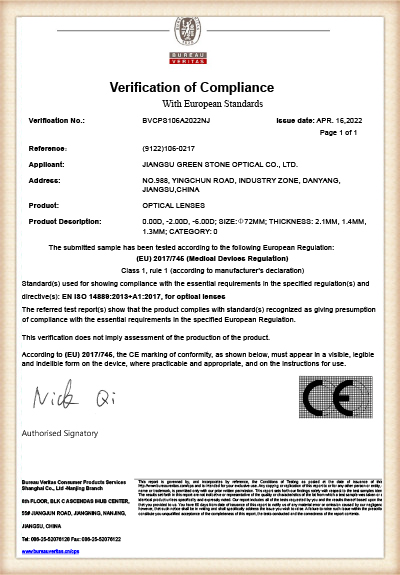

MOQ: 1 Pasang (Bespoke). Makmal Ketepatan Gred Perubatan.