Pengenalan Produk

Keajaiban Kejuruteraan: Mengapa MR-8 adalah Pilihan Profesional

Dalam dunia resin optik, indeks 1.61—khususnya menggunakan monomer MR-8™—dianggap secara meluas sebagai bahan indeks tinggi paling seimbang yang pernah dicipta. Walaupun indeks yang lebih rendah mengutamakan kos dan indeks yang lebih tinggi mengutamakan kenipisan, MR-8 menawarkan gabungan unik kekuatan tegangan tinggi, nilai Abbe tinggi (kejelasan optik) dan rintangan haba yang unggul. Ini menjadikannya "Gold Standard" untuk bingkai separa tanpa bingkai dan tanpa bingkai (lekap gerudi). Tidak seperti resin standard yang boleh retak atau mengelupas apabila digerudi, bahan MR-8 adalah sangat lasak dan fleksibel, memastikan integriti cermin mata walaupun dalam tekanan fizikal. Dari perspektif optik, nilai Abbe 41 memastikan penyimpangan kromatik kekal minimum, memberikan pengalaman tontonan yang jelas dan selesa yang menandingi bahan indeks rendah tetapi dengan profil tepi yang lebih nipis. Kanta ini kira-kira 25-30% lebih nipis daripada 1.50 kanta, menjadikannya ideal untuk preskripsi antara -3.00D hingga -6.00D. Siri 1.61 kami diproses menggunakan tuangan cecair berketepatan tinggi, menghasilkan kanta yang bukan sahaja menyenangkan dari segi estetika tetapi juga serasi secara biologi dan sangat tahan lama. Bagi pesakit yang menjalani kehidupan profesional yang aktif dan memerlukan kanta yang ringan dan sangat kuat, 1.61 MR-8 adalah cadangan muktamad.

[Imej: Perbandingan ketebalan tepi 1.61 MR-8 vs kanta standard]| bahan | Monomer MR-8 tulen |

| Nilai Abbe | 41 |

| Graviti Tertentu | 1.30 g/cm³ |

Sorotan Teknologi: Monomer Premium dan Integriti Salutan

- Pemilihan Monomer Ketulenan Tinggi: Kami secara eksklusif menggunakan monomer berprestasi tinggi (mis., siri MR) untuk mencapai kekuatan tegangan dan ketulenan optik yang unggul, menghasilkan kejelasan yang sangat baik dan risiko minimum menguning dari semasa ke semasa.

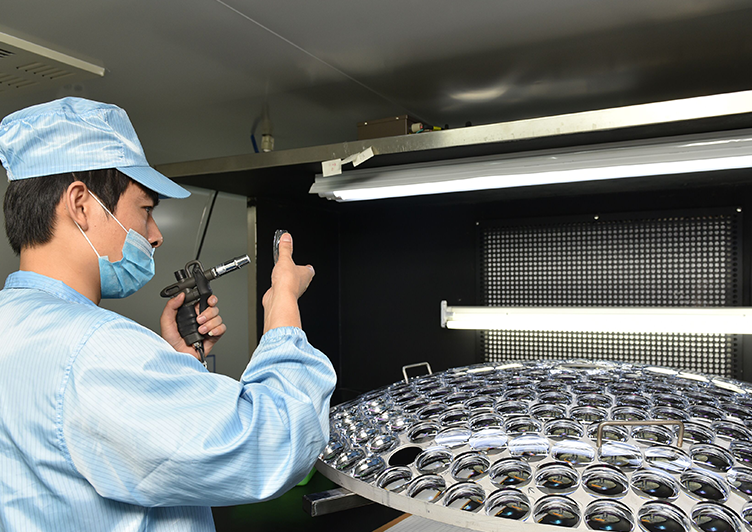

- Proses Tuangan Cecair Ketepatan: Kanta dihasilkan melalui kaedah tuangan cecair terkawal yang memastikan ketumpatan bahan seragam dan konsistensi indeks biasan merentas keseluruhan kosong, yang penting untuk zon kuasa terapeutik yang tepat.

- Salutan Berbilang Vakum Lanjutan (SHMC): Salutan digunakan dalam ruang vakum tinggi, menggunakan pelbagai lapisan oksida logam untuk mencipta tindanan anti-reflektif yang tahan lama. Proses ini menjamin penghantaran cahaya maksimum dan silau minimum.

- Pengoptimuman Pengawetan Terma: Kitaran pengawetan haba yang perlahan dan tepat digunakan untuk memaksimumkan rintangan bahan terhadap tekanan dalaman, memastikan kanta siap kekal stabil dan sempurna dari segi optik dalam keadaan suhu yang berbeza-beza.

- Geometri Nyahfokus Periferi Bersepadu: Reka bentuk terapeutik direka bentuk ke dalam acuan itu sendiri untuk kanta tuang, atau digunakan melalui permukaan digital untuk kosong separuh siap, menjamin ketepatan dan konsistensi geometri zon kawalan rabun.

- Bingkai Tanpa Rimless & Semi-Rimless

- Miopia Sederhana hingga Tinggi

- Penggunaan Profesional Beraktiviti Tinggi

- Kekuatan Tegangan Unggul

- Kejelasan Optik Cemerlang

- Profil Nipis & Ringan

-

0+

Pengalaman Bertahun

-

0㎡

Kawasan Loji

-

0+

Dieksport ke Negara

-

0juta kanta

Kapasiti Tahunan

Penyesuaian

Disesuaikan Untuk Anda

Perniagaan

-

01

Keupayaan Penyesuaian Lengkap

-

02

Seni Bina Kanta Profesional

-

03

Penyesuaian Salutan Fungsian

-

04

Penyesuaian Rx Digital

-

05

Penjenamaan & Pembungkusan

-

06

Penghantaran & Sokongan

- S: Mengapakah MR-8 lebih baik untuk bingkai tanpa bingkai?

- A: Ia mempunyai impak yang tinggi dan kekuatan tegangan, menghalang keretakan pada lubang gerudi.

- S: Sejauh manakah ia nipis berbanding dengan kanta standard?

- A: Ia adalah kira-kira 25% hingga 30% lebih nipis daripada 1.50 kanta indeks.

- S: Adakah ia mempunyai warna kuning?

- A: Tidak, MR-8 gred tinggi menyediakan asas yang jernih dan tidak berwarna.

- S: Adakah ia sesuai untuk astigmatisme tinggi?

- A: Ya, ia memberikan kestabilan yang sangat baik untuk preskripsi yang kompleks.

- S: Adakah ia menghalang cahaya UV?

- A: Ya, ia mempunyai perlindungan 100% UV400 bersepadu.

- S: Apakah julat kuasa?

- A: Biasanya stok dari -10.00 hingga 6.00.

- S: Bolehkah ia berwarna?

- A: Ya, walaupun ia memerlukan pewarna lebih perlahan daripada CR-39, ia mewarna dengan cantik.

- S: Adakah salutan tahan lama?

- A: Ya, bahan terikat dengan sangat baik dengan salutan AR dan SHMC.

- S: Bagaimanakah kejelasan dibandingkan dengan 1.67?

- A: 1.61 mempunyai nilai Abbe yang lebih tinggi, bermakna kejelasan optik yang lebih baik sedikit.

- S: Adakah ia tahan panas?

- A: Ya, ia mempunyai suhu ubah bentuk yang tinggi, sesuai untuk kestabilan salutan.

T/T, PayPal. Penghantaran 7-10 Hari.

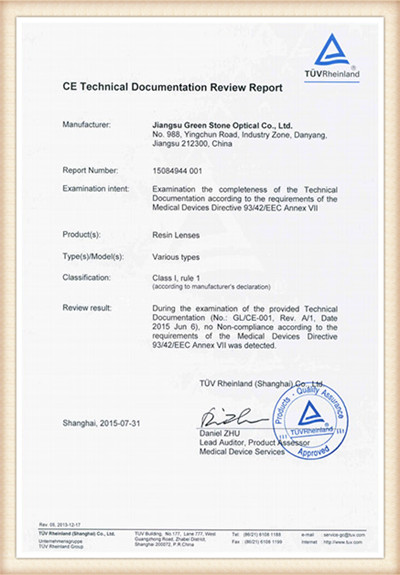

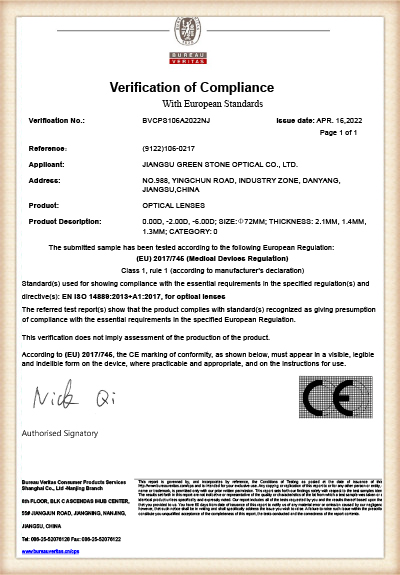

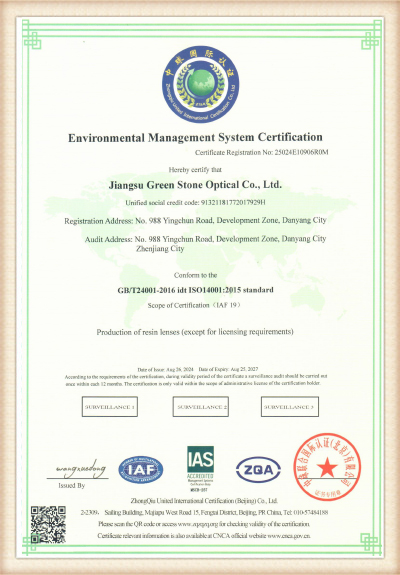

MOQ: 50 pasang. Diperakui CE/ISO.